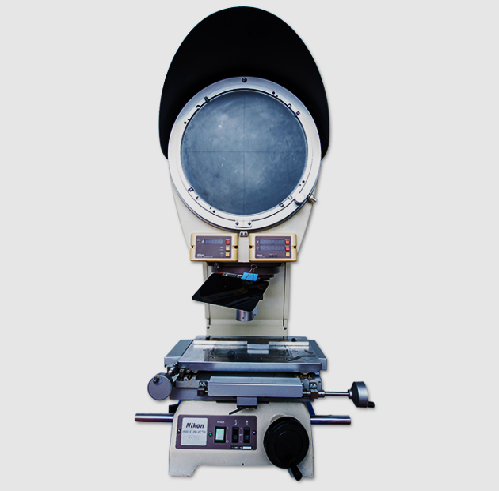

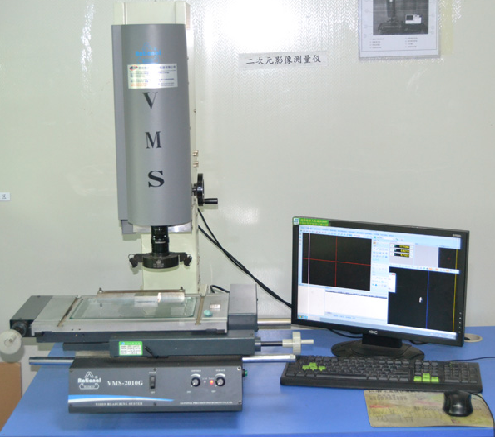

Inspector Device

Inspector Device

Inspector Device

Quality Assurance

In the Quality Assurance Department at GM Mold each plastic part’s inspection plan is customized to provide top quality parts to you, without adding additional unnecessary cost. In addition to utilizing Statistical Process Control to maintain a part’s dimensional characteristics post molding. Real Time Statistical Process Control is utilized during the injection molding process to provide shot to shot quality. These features along with our dedication to provide top quality parts allows us to meet and exceed your most stringent injection molded part requirements.

Quality Control Process

The inspection process at GM Mold. starts when a new mold/product is brought to us. The sample parts and drawings are reviewed for critical dimensions or areas that we will have to pay special attention to. The inspection sheets are generated by these findings.While the parts are cooling they will be visually inspected for any non-conformity such as short shots, flashing and splay to name a few. If there are any cosmetic issues those will be addressed first with production and corrected and new shots pulled.

If all is acceptable visually after the cooling period the product is dimensionally inspected per the prints and inspection sheet. Using hand tools i.e. calipers, micrometers, gage pins or drop indicator or the C.M.M.

Inspector Device

Inspector Device